Experiment 1: THE EFFECT OF DIFFERENT AMOUNT OF PEG

ON THE PHYSICAL CHARACTERISTICS OF SUPPOSITORY

Title:

The effect of different amount of PEG on the

physical characteristics of suppository.

Objectives:

1.

To calibrate

suppository mould with PEG before preparing medicated suppositories.

2.

To determine

the effect of different compositions of PEG base on the physical

characteristics of suppositories.

Date

of experiment:

7th March 2017

Apparatus

and Materials:

Analytical

balance, 1 x suppository mould set, water bath at 37o C ,1 x

spatula, hotplate, 4 x weighing boats, 4 x 50 mL beaker, 2 x glass rod, 1 x 5

mL pipette and pipette bulb, 1 x 5 mL measuring cylinder, polyethylene glycol

(PEG)1000, distilled water, polyethylene glycol (PEG) 6000, liquid paraffin,

and paracetamol.

Introduction:

Suppositories

are solid dosage forms of various sizes, appearance (shapes) and weights

intended for administration by rectal route where they melt, soften or dissolve

to exert their effect. They are capable of being easily inserted into the

intended orifice without causing undue distention. The suppository usually

composed of a medicament incorporated (dissolved or suspended) in a suppository

base, this medicament may be intended for retention within the cavity for

localized drug effect or to be absorbed for the exertion of systemic effect.

For example, rectal localized action such as relief of constipation, pain,

itching and inflammation associated with hemorrhoid conditions.

Suppositories

are indicated for systemic action in pediatric patients and in patients who

cannot take or tolerate oral medication due to variety of reasons e.g. to

relief nausea, vomiting and pain. The drug must be spread in a suitable base of

suppository. Ideal suppository bases should be easily formed by compression or

molding; release any medicament readily; melt at body temperature or dissolve

or disperse in body fluids; keep its shape when handled; compatible with the

drugs, non-irritant and non-toxic.

Polyethylene

glycol (PEG) polymers have received much attention as suppository bases in

recent years because they possess many desirable properties. They are

chemically stable, non-irritating, miscible with water and mucous secretions,

and can be formulated, either by molding or compression, in a wide range of

hardness and melting point. Moreover, they do not melt at body temperature, but

dissolve to provide a prolonged release. Certain PEG polymers may be used

singly as suppository bases but, more commonly, formulas call for compounds of

two or more molecular weights mixed in various proportions as needed to yield a

finished product of satisfactory hardness and dissolution time.

Methodology:

A.

Calibration of Suppository Molds with PEG Base.

For

this calibration exercise, 10g of the following proportions of PEG 1000 and PEG

6000 are used.

Ingredients

|

Percentage

|

Weight Basis

|

PEG 1000

|

60%

|

6g

|

PEG 6000

|

40%

|

4g

|

To

calibrate the mold with PEG suppository base:

1.

Clean

and dry mold was used. The mold was not lubricated.

2.

PEG

1000 was melted on a steam bath or hot plate. Then, the heat was reduced and

mixed in the other PEG.

3.

The

mixture was removed from the heat and it was allowed to cool before pouring

into the mold.

4.

The

cavities of the mold were overfilled with the mixture of the PEG 1000 and PEG

6000. It was left at room temperature until it become solid.

5.

The

excess was removed with a hot spatula. Then, the suppositories were removed

from the mold.

6.

The

suppositories were weight and the total weight was recorded. The average weight

of the suppository was calculated.

B.

Preparation of paracetamol suppositories.

1.

Saturated

stock solution of paracetamol was prepared by adding 10g of paracetamol in 5 mL

of distilled water.

2.

The

paracetamol suppository (10g) was prepared by using the following formulation:

Suppository

|

PEG 1000 (g)

|

PEG 6000 (g)

|

Paracetamol stock solution (mL)

|

Total (g)

|

I

|

9

|

0

|

1

|

10

|

II

|

6

|

3

|

1

|

10

|

III

|

0

|

9

|

1

|

10

|

3.

One

type of PEG was melted on a steam bath or hot plate. Then, the heat was reduced

and being mixed in the other PEG.

4.

The

mixture was removed from the heat and it was allowed to cool before pouring

into the mold.

5.

The

cavities of the mold were overfilled with the mixture of PEG 1000 and PEG 6000.

It was left at room temperature until it become solid.

6.

The

excess was removed with a hot spatula. Then, the suppositories were removed

from the mold.

7.

The

shape, texture and color of the suppositories were observed.

8.

Each

of the suppositories was put into a separate beaker containing distilled water

(10 mL and pre-warmed at 37o C). Then, the beaker was put into a water bath (37

o C).

9.

The time for

the suppositories to melt was recorded.

Results

10g of the

following proportions of PEG 1000 and PEG 6000 were used for calibration

exercise.

Ingredients

|

Percentage

|

Weight Basis

|

PEG

1000

|

60%

|

6.0g

|

PEG

6000

|

40%

|

4.0g

|

Part 3.3.1

No of mold

|

1

|

Total weight for 6 suppositories (g)

|

6.0708

|

Average weight for 1 suppositories (g)

|

6.0708/6 = 1.0118

|

Part 3.3.2

Suppository

|

Shape

|

Texture

|

Colour

|

I

|

Bullet

|

Soft, greasy

|

Clear white

|

II

|

Bullet

|

Hard. smooth, slightly greasy

|

Cloudy white

|

III

|

Bullet

|

Hard, smooth, less greasy

|

White

|

Amount of PEG 6000 (g)

|

0

|

3

|

9

|

Time (mins)

|

7.30

|

5.25

|

7.58

|

DISCUSSION

1.

Describe the important of calibrating suppository mould before preparing

medicated suppository.

Each individual mold is capable of

holding a specific volume of material in each of its openings. The difference

in the densities of the materials will produce suppositories with different

weights. Any added medicinal material will affect more the weight of both bases

and amount of suppository that are able to be put into the mold. Calibrating

suppository mould before preparing medicated suppository is to make sure that

the mould produce an equal size and weight for each of the suppositories. It is

to ensure accurate dosing.

2. Compare the physical appearance

of suppositories that are formed and discuss.

Suppository

|

Shape

|

Texture

|

Colour

|

I

|

Bullet

|

Soft, greasy

|

Clear white

|

II

|

Bullet

|

Hard. smooth, slightly greasy

|

Cloudy white

|

III

|

Bullet

|

Hard, smooth, less greasy

|

White

|

The table above refers to the comparison

of the physical appearance of suppositories with different compositions of PEG

base that are formed during the experiment. The two main bases involved are PEG

1000 and PEG 6000. These PEGs are blended together to produce several

suppository bases with different melting point and physical

characteristics.

All of the suppositories possess the same shape which is bullet shape,

due to the shape of the mould used for

the making of the suppositories.

The melting point of PEG increases with

the rise of the molecular weight of PEG. So, suppository III is the hardest

among all of the suppositories due to the high amount of PEG 6000. Suppository

I possess a high amount of PEG 1000 which explain the soft, gel-like texture.

Suppository III has a flaky texture which

is different from the other two suppositories which also due to the high amount

of PEG 6000. High molecular weight PEG such as PEG 6000 has a high melting point which leads to harder,

brittle and flaky form of suppository formed. As the molecular weight of the

PEG increase, the hygroscopicity decreases. This result in suppository III

showing the least greasiness appearance compared to suppository I and II.

All of the suppositories are in white colour due to the even dispersion of paracetamol

powder in the suppository base. Nonetheless, the suppositories possess a different

intensity of cloudiness. Suppository III has a high

amount of PEG 6000, hence giving it wax-like, white color solid.

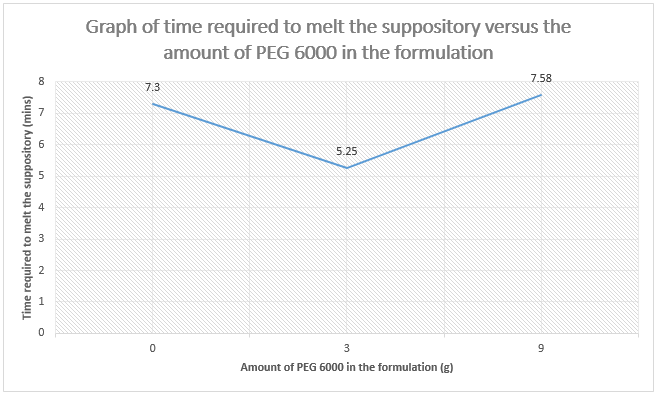

3.

Plot a graph of time required to melt the suppository vs. the amount of PEG

6000 in the formulation. Compare and explain the results.

The objective of this

experiment is to determine the time taken for the paracetamol suppository to

melt at the mimic of constant body temperature (37°C ) depends on the

concentration of Polyethylene glycols 6000 (PEG 6000) contained in the suppository. PEG is

generally used as base for suppository due to it is water soluble, inert,

non-ionic and most polar organic solvent. Different molecular weight of PEG will result

in various physical parameters of the products such as solubility, melting

point, freezing point and surface tension.

Theoretically, the molecular weight of PEG is directly proportional to

the melting point of the suppository. The higher the molecular weight of PEG,

the higher the melting point of the suppository. Hence, PEG 6000 has higher

melting point compared with PEG 1000 as their average molecular weight are

between 5000-7000 and 950-1050 respectively. From the graph above, we can conclude

that the amount of PEG 6000 also influences the melting point of the

suppository. As the concentration of PEG 6000 increases, the amount of energy

needed to overcome the attraction force between the paracetamol and PEG

particles increases, therefore more time is required to breakdown the bonds

between the molecules of the compound.

However, the result

that we obtained from the experiment is different from the theory. There is a

decrease in time taken for the suppository containing 0g of PEG 6000 to 3g of

PEG 6000 suppository and then drastically increases in the length of time taken

from 3g to 9g of PEG. This is considered that the experimental result is

deviated from the original theory as supposedly the 0g PEG suppository will

have the faster rate in melting process. This probably maybe caused by several

errors when we carried out the experiment. One of the errors is we could not

accurately observe and determine whether the suppository started to melt in the

37°C water bath with naked eyes. When we took out the beaker from the water

bath, we required looking carefully the small particles dispersed in the water

to indicate that the suppository started to melt and then it took time and led

to the inaccuracy of time recording. In addition, the temperature of the water

in the beaker should be consistent measured to ensure the water temperature was

maintained at 37°C due to it was conducted in open air condition. Moreover, the

rate of melting process of the suppository maybe affected by the inappropriate size

of beaker (50mL beaker was used) being used that hindered an even distribution

of heat throughout the suppositories. It is suggested that using test tube

instead of using the beaker so that even distribution of the heat can be

contributed to the suppositories.

4.

Describe function(s) of each ingredients used in the suppository formulation.

The ingredients used in preparing paracetamol

suppository formulation included polyethylene glycol (PEG) 1000, polyethylene

glycol (PEG) 6000, paracetamol, distilled water and liquid paraffin.

Polyethylene glycol (PEG) polymer is

commonly used as suppositories base due to it characteristics like

water-miscible and chemical stability. The characteristics of hardness, melting

point and dissolution time of PEG mainly depends on different molecular weight

of PEG types. PEG 1000 is a low molecular weight PEG, and when it is used

alone, it produced a soft suppository that is theoretically, would dissolute

and release the loaded drug fast. Whereas PEG 6000 is a high molecular weight

PEG, and when it is used alone, would produce hard and brittle suppositories,

thus causing a low release rate of drug. A good quality of base could be established when there is a combination of

right ratio between high molecular weight and low or medium molecular weight

PEG. The satisfactory or desirable hardness, melting point and dissolution

could then be achieved by altering the ratio of PEGs combined.

Besides,

paracetamol is the active ingredient for suppositories. It is used for

analgesic and anti-pyretic purposes. Paracetamol is dissolved in distilled

water as a solvent to form paracetamol solution.

Distilled

water is used as a solvent to incorporate a water-soluble substance in the

suppository base.

Whereas, liquid paraffin is used to

lubricate the mold before the solution filled in it. This is to ensure that the

suppositories does not stick to the mould and can be removed easily without the

cracking of suppositories.

Conclusion:

Calibrating suppositories mould with PEG before

preparing medicated suppositories is important as it ensures accurate dosing of

suppositories to be produced for the patients. Different compositions of PEG

base will affect the physical characteristics of the suppositories produced,

including their physical appearance, colour, hardness, greasiness and time

taken to start melting. When the highest

amount of PEG 6000 base is used to prepare the suppositories, the suppositories

produced are the hardest, smoothest, least greasy and are clear white in

colour. They are also most difficult to be melted as the longest time is taken

to let it start melting.

References: